When you need foundation repair in Charlotte, North Carolina, you look for a trusted name — Tar Heel Foundation Solutions. We take pride in using the latest and most up-to-date products on the market, including our steel push piers. This allows us to stay at the top of our game and keep your home on top of its stable foundation.

We are a preferred installer of ECP, Earth Contact Products. The most commonly used item is the Model 300 steel pier for underpinning repairs. It allows your home to rest on a stable footing and hold up to its proper load-bearing standards.

The pier is designed to drive deep into the soil to support structures from the interior and exterior of the foundation. It bypasses all of the active soils to do so. It is the leader of steel piering systems and is quickly becoming well-known for being the strongest and deepest driving pier system around.

This pier is an end-bearing pier, which means that it does not rely on any type of friction to produce the support it provides. We load test all piers before installing them to ensure they meet all standards and will produce the type of support needed for the repair. The pier’s design ensures maximum weight will be supported during and after restoration and load transfer.

We drive the piers individually, restoring the entire structure as a reaction. The friction reduction collar that is attached to the lead section of the pier pipe creates an opening in the soil. This both reduces the friction and allows the installer to load test the pier. They then verify when the pier reaches a firm rock or stratum for maximum stability.

Our technicians attach high-pressure jacks in many locations around the foundation of the home and maneuver them by a hydraulic manifold. This reduces the load on the individual piers as well as only allowing for the designed working load to be transferred to each pier.

|   |

|   |

First, our technicians choose pier placements and verify the location of underground.

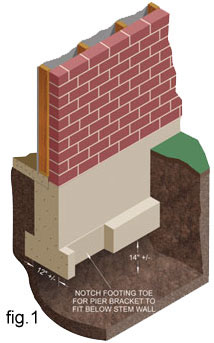

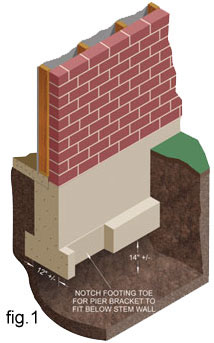

We then dig small excavations for access at each placement location. The space required at the foundation is usually about 3 feet square. (fig 1)

This includes notching the footing (if required) to place the pier bracket under the stem wall, preparing the bearing area under the footing to a smooth and level condition, and adjusting the face of the stem wall to vertical (plumb) at the point of bracket attachment. (fig 1)

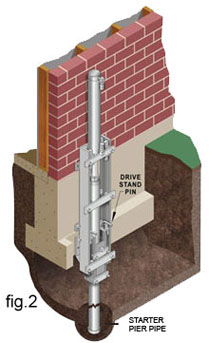

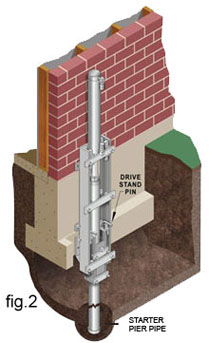

A technician then secures the utility bracket to the footing using anchor bolts. We attach the drive stand and mount the hydraulic cylinder that we use to force the pier pipe into the soil onto the drive stand. (fig 2)

We advance the pier pipe into the soil using the structure as the reaction force with a 10,000 psi hydraulic pump and cylinder combination. The piers may be installed either from outside or inside the structure. Pier installation continues until rock or suitable bearing-strata is encountered below the unstable soil near the surface. (fig 2)

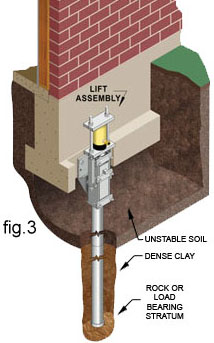

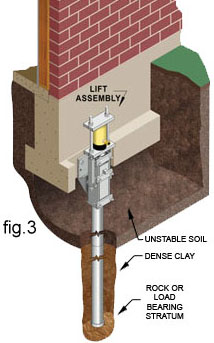

Our technicians load test every pier by increasing the force on the pier to ensure the rock or bearing-strata will support a load greater than needed to guarantee a factor of safety. Typically an engineer will determine the load of the structure and the desired factor of safety before we perform the load tests. (fig 3)

Once we have installed and load tested each pier and recorded the installation data at each placement, we place the lifting head assemblies and hydraulic lifting rams on the piers. The lifting cylinders are then connected with one or more manifolds and operated using a hydraulic pump. (fig 3)

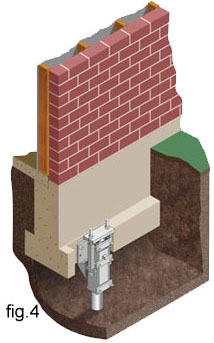

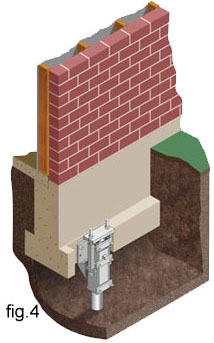

Under careful supervision, our technicians then transfer the load from the existing failing strata under the foundation to the load-tested piers. The structure can be transferred gently and evenly lifted to as close to the original elevation or to the recommendation of the engineer. We secure the nuts at the pier caps at each placement and remove the lifting equipment. (fig 4)

Finally, we replace and compact the soil excavated at each pier placement and leave the site neat and clean.